Besides taxes and special fees, most commercial/industrial rate schedules bill for consumption in two ways: (1) the number of kilowatts required multiplied by the number of hours or “total consumption” measured in kWh, and (2) the maximum volume of kilowatts required to meet load demands at any point in time or “demand” measured in kW. Energy Demand tends to be one of the most misunderstood items on the bill, but in order to understand it properly, we must also understand kWh. This article is meant to answer the question—What is energy demand?

Energy Demand vs. Consumption

kWh represents the amount of energy required multiplied by the number of hours over which it is consumed. For example, a 1,000 watt (1 kW) heater running for one hour has used 1 kilowatt-hour or 1 kWh. If it runs for 24 hours, it will consume 24 kWh. A 15,000 watt heater would consume 15 kWh in one hour or 360 kWh in 24 hours. If each heater were on a separate meter with no other loads or power sources, the demand would be 1 kW on the first meter and 15 kW on the second – no matter how long they run.

In other words, total consumption adds up over time while demand refers to the volume of power required at any given point in time. Demand is what has the most direct impact on the capacity requirements of the power source and all the components (wire, transformers, breakers, etc.) that connect the source to your load. Higher demand requires higher delivery capacity.

A Plumbing Analogy

In plumbing terms, a typical 1 inch supply pipe to your house can deliver, under typical pressure, about 37 gallons of water per minute – assuming no flow restrictions imposed by faucets, etc.

If, however, you require 100 gallons per minute – even if only for 5 minutes each month – you would need a 2 inch supply pipe and the water company would have to be able to produce that much more water while maintaining pressure. Since it costs more to provide that level of pressure and flow (e.g., 2 inch pipe costs considerably more than 1 inch), they would charge extra to cover their costs.

Energy Demand Based on Peaks

Returning to the power discussion, most power companies calculate your demand charge based on your highest volume 15-minute period in the month. This might have very little to do with your monthly total consumption. It simply represents the capacity in wire size, transformer size and generation that the power company must provide to meet your high demand events or peak periods. That capacity must always be available, even if you only need it for one very brief period during the month, and since there is a real cost associated with increased capacity, the power company will charge you for it.

Demand Double Dipping?

I’ve heard some complain that the power companies are double-dipping when they apply these charges. I would reiterate that it takes far less capacity to deliver 100 kWh in the form of 1 kW over 100 hours than in the form of 6,000 kW over one minute. If the only charge were for the kWh’s consumed, both of these examples would be charged the same amount, but the power company would have to increase the cost per kWh for everyone in order to cover their costs for the high demand example. This would clearly be unfair to the low demand customers, so keeping the cost per kWh low for everyone and charging customers an additional demand charge based on their specific peak demand really is more fair.

Getting a Handle Energy Demand

We’ve seen businesses with high demand profiles where the demand portion of the power bill is as much as 65% of the total bill. In such cases, reducing the demand can have a much higher impact on overall energy costs than reducing consumption. But how do we do that?

What are some of the more common ways of reducing demand?

Reducing Energy Demand

Hopefully, we’ve answered “what is energy demand?” as well as understand a little better why high demand has such an impact on power company costs and why they want and why it’s fair for them to charge a separate fee for it. Now I’ll cover ways to reduce demand.

Plumbing Revisited…

You’ll recall our plumbing analogy. One customer wanted a higher volume of water flow and needed to build capacity into the system for that volume of flow. It might be fair to ask why they needed so much capacity.

A perfectly valid reason might be that they are running a manufacturing process that requires a lot of water. This is a constant requirement. Reducing flow would likely also reduce production unless they can first upgrade to newer manufacturing equipment that runs more efficiently. At any given point in time, neither option is likely available to them.

Staggering Implications!

But what if they simply have three occupants in a house who all want to take a bath at the same time each evening in three separate tubs? In order to fill all three tubs at the same time and without delay, they need a high capacity system, but otherwise they have no need for such capacity. To most of us, this example would seem silly. Rather than pay for a high capacity system, it would be much cheaper to simply stagger their bath times. Right?

But as silly as that example seems, we see its equivalent all the time. Perhaps a pump house has two large pumps. Startup demand is high for each pump but run-time demand is much lower. Starting them both at the same time can double the peak demand. On the other hand, staggering their starts by even 30 seconds can keep the peaks down nearly to individual levels. Unless there’s a very good reason for starting them at the same instant, why not stagger? It could save gallons of money.

Control Your Startup Procedures.

What do your startup procedures look like? When a shift begins, does someone simply hit the switches and go? Or is there an orderly startup procedure that minimizes simultaneous motor and ballast starts? Programmable logic controllers can automate these processes and eliminate the human error factor. Remember that the demand charge is based on the one highest peak during the month so if someone forgets to follow manual procedures – even once during the month – your demand charges are fixed by that one event. Automation solves that problem.

Other Potential Savers:

- Putting soft starts or VFDs on larger motors. These can help reduce peak demand amplitude.

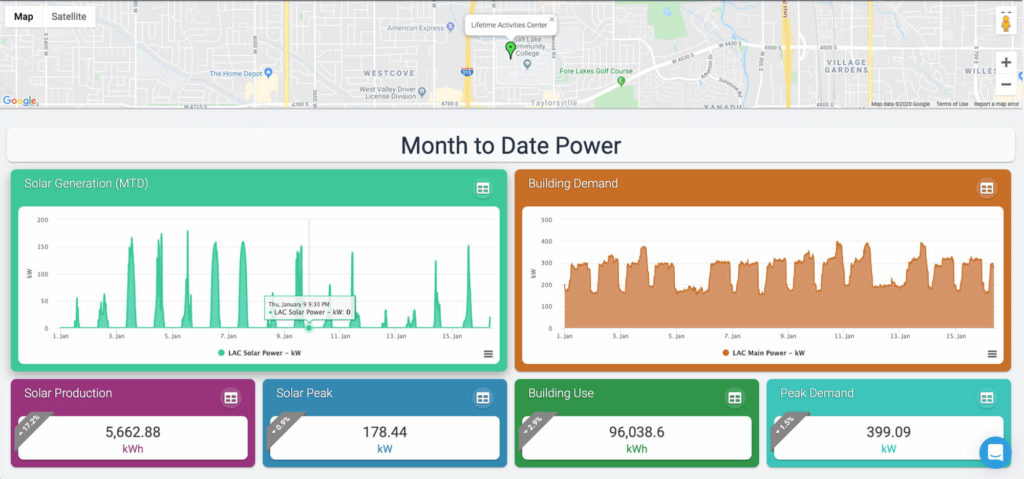

- If you have supplemental power, such as cogeneration or maybe solar, try to time all of your high demand events so that they occur while supplemental power is producing. This can take some of the base out from under the demand peaks and reduce peak amplitude. Remember, however, that solar power can do nothing to reduce night-time demand peaks unless you have battery systems that spread the solar production throughout the day and night. Once again, without storage it only takes one cloudy day to frustrate your efforts, which makes PV solar an unreliable method for reducing demand.

- As equipment wears out, replace it with equipment that utilizes energy more efficiently.

- Make sure your power factor is good. Low power factor can increase the amplitude of demand peaks. Be cautious, however, when shopping for power factor correction devices. Traditional capacitor solutions can magnify harmonic distortions and increase the likelihood of harmonic resonances which can damage your equipment and shorten the life of the capacitors.

Meter, Meter, Meter!

Finally, and perhaps most importantly, it is virtually impossible to correct for the problems you don’t know about. If you really want to solve your demand and other energy problems, we recommend real-time power metering and analytics. By knowing exactly what is going on with your power consumption and demand, you can implement customized mitigation strategies to reduce your bills and increase profitability. Please Click Here to learn how VITALITY can help you with your energy metering challenges.